Services

Deep Hole Drilling

-

Introduction to Deep Hole Drilling

There are three basic types of deep hole drilling. Processes are categorized by how the cutting coolant flushes heat and chips from the cutting surface. The three types of deep drilling are:

Gun Drilling - The cutting tool is a fluted solid rod that has a hole bored down the center. Coolant is pumped through a hole in the inside of the drill. It flows back outside the drill, through the flute, bringing the chips with it.

BTA / STS (Boring and Trepanning Association/Single Tube System) - The cutting tool is a tube. Coolant is pumped in around the outside of the cutting tool and carries chips out through the centre tube. Because tubes have minimum sizes, this is only an acceptable technology for holes of over 15.6mm in diameter.

Ejector Drilling - The cutting tool is a tube with another inner tube nested inside. Coolant flows through between the inner tube and the outer to the cutting face and then coolant and chips flow back through the inner tube. This is only an acceptable technology for holes of over 18.4mm in diameter.

We would be happy to help you determine the best type of drilling and finishing for your application, contact us regarding your next project.

Ejector or Double Tube System Drilling

-

Robot Production Cell

DHDS operat 2 ABB 800kg Payload robots for deep hole driling and machining. This not only allows for increase productivity but also more importantly WH&S.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

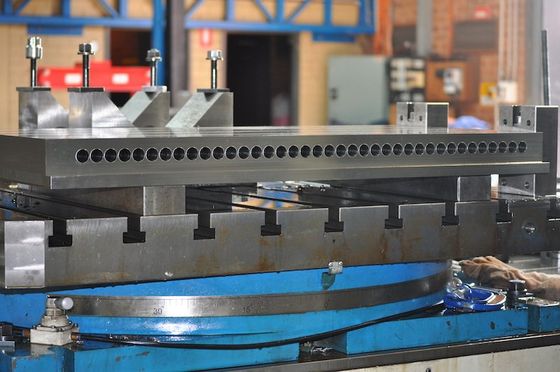

Off Centre and On Centre Drilling

-

DHDS offer On and Off Centre drilling applications

DHDS offers On and Off Centre Ejector or BTA drilling with hole diameters ranging from 25 to 130 mm, and depending upon the required diameter, up to 5000mm. Longer depths can be achieved on application.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

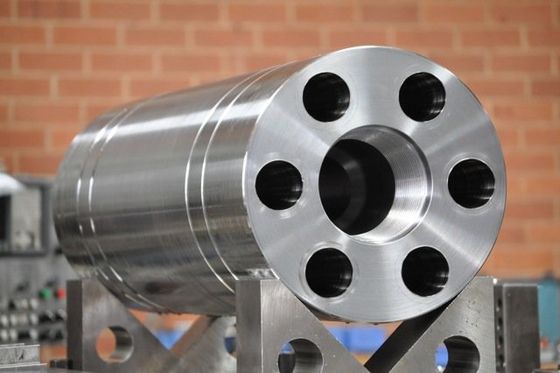

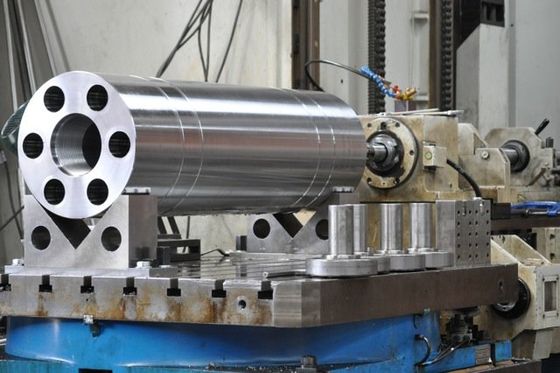

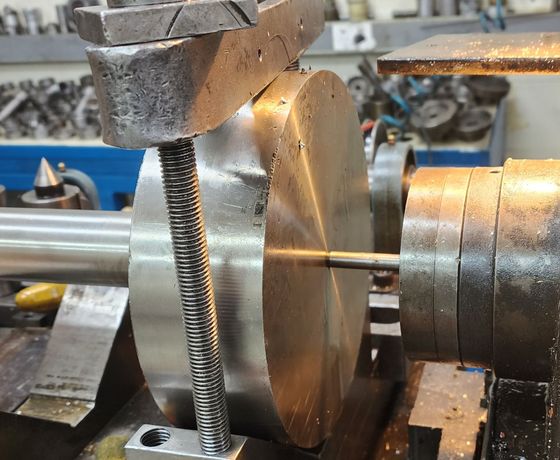

Ejector or BTA Drilling

-

Gun drilling is a form of deep hole drilling that ....

Gun drilling is a form of deep hole drilling that produces deep, straight holes in various materials. Gun drilling differs from BTA/Ejector drilling due to the coolant entry and chip removal.

At DHDS we have the capacity to drill at a range of different angles to suit your individual application.

Slide title

Write your caption hereButton

All Rights Reserved | DEEP HOLE DRILLING SPECIALISTS